Module 8 – Making Procurement Work

If time, cost, and quality are key ingredients of projects and linked to determine the successful outcome (deliverables) of the project, then Procurement is a major factor. The purchasing (also described as acquisition or procurement) of materials, equipment, facilities, staff, consultants, sub-contractors, information systems, supplies, and the myriad of other resources that may be required is a major function in ensuring time, cost and quality targets are met. Effective procurement not only enables cost requirements to be met, but affords real opportunities to reduce costs, improve quality (performance), and save time in the project.

In the past, the procurement function was often regarded as a minor off-shoot to manufacturing or production in many organisations. Today, it is appreciated by most managers that procurement represents the major expense in operations and so efficiencies in arranging contracts for the supply of resources represent a major opportunity to reduce overall costs and improve profitability.

Procurement is a strategic function and a major logistic activity in both project and non-project-oriented organisations. Consider a not-for-profit organisation such as the Red Cross. Procurement of all the equipment, supplies, packaging and materials for the Blood Bank service is a major cost and an opportunity to reduce expenses. Inventory can be minimised through effective supply chain management and the adoption of just-in-time supply.

Similarly, a modern hospital procures a huge range of equipment, supplies, materials, disposables, and cleaning and sterilisation services. With tight budget limits and ever-growing demand for health services, the procurement function is key in ensuring that hospitals can carry out their role while meeting patient service targets.

In projects, the stages of procurement – identifying needs, agreeing on specifications, identifying suppliers, negotiating acceptable prices, arranging contracts, managing timely and accurate delivery of required items, ensuring minimum loss, wastage, shrinkage and theft and delivering the right goods and services in the right place, at the right time, in the right quantity, in the right condition, in the right quality, and at the right price – are critical to overall project performance.

Procurement management follows a logical order. First, you plan what you need to contract; then you plan how you’ll do it. Next, you send out your contract requirements to sellers. They bid for the chance to work with you. You pick the best one, and then you sign the contract with them. Once the work begins, you monitor it to make sure that the contract is being followed. When the work is done, you close out the contract and fill out all the paperwork.

You need to start with a plan for the whole project. Before doing anything else, you need to think about all of the work that you will contract out for your project. You will want to plan for any purchases and acquisitions. Here’s where you take a close look at your needs to be sure that contracting is necessary. You figure out what kinds of contracts make sense for your project, and you try to define all of the parts of the project that will be contracted out.

Contract planning is where you plan out each individual contract for the project work. You work out how you’ll manage the contract, what metrics it will need to meet to be considered successful, how you’ll pick a seller, and how you’ll administer the contract once the work is happening.

The procurement management plan details how the procurement process will be managed. It includes the following information:

- The types of contracts you plan to use and any metrics that will be used to measure the contractors’ performance

- The planned delivery dates for the work or products you are contracting

- The company’s standard documents you will use

- The number of vendors or contractors involved and how they will be managed

- How purchasing may impact the constraints and assumptions of the project plan

- The coordination of purchasing lead times with the development of the project schedule

- The identification of prequalified sellers (if known)

The procurement management plan, like all other management plans, becomes a subsidiary of the project management plan. Some tools and techniques you may use during the procurement planning stage include make-or-buy analysis and definition of the contract type.

Make-or-Buy Analysis

This means figuring out whether or not you should be contracting the work or doing it yourself. It could also mean deciding whether to build a solution to your problem or buy one that is already available. Most of the same factors that help you make every other major project decision will help you with this one. How much does it cost to build it as opposed to buying it? How will this decision affect the scope of your project? How will it affect the project schedule? Do you have time to do the work and still meet your commitments? As you plan out what you will and won’t contract, you need to think through your reasoning very carefully.

There are some resources (like heavy equipment) that your company can buy, rent, or lease depending on the situation. You’ll need to examine leasing-versus-buying costs and determine the best way to go forward.

Contract Types

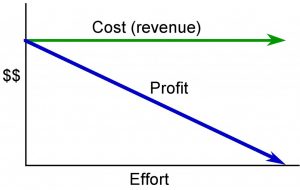

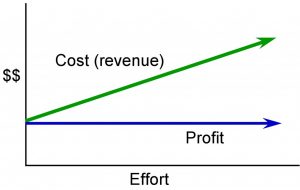

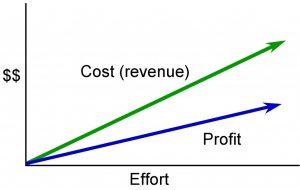

You should know a little bit about the major kinds of contracts available to you (the client) so that you choose the one that creates the most fair and workable deal for you and the contractor. Some contracts are fixed price: no matter how much time or effort goes into them, the client always pay the same. In Figure A the cost to the client stays the same, but as more effort is exerted the profit to the contractor goes down. Some are cost reimbursable also called cost plus. This is where the seller charges you for the cost of doing the work plus some fee or rate. Table A illustrates this by showing that as efforts increase, costs to the client go up but the contractor’s profits stay the same. The third major kind of contract is time and materials. That’s where the client pays a rate for the time spent working on the project and also pays for all the materials used to do the work. Figure B shows that as costs to the client go up, so does the profit for the contractor.

Fixed-Price Contracts

The fixed-price contract is a legal agreement between the project organization and an entity (person or company) to provide goods or services to the project at an agreed-on price. The contract usually details the quality of the goods or services, the timing needed to support the project, and the price for delivering goods or services. There are several variations of the fixed-price contract. For commodities and goods and services where the scope of work is very clear and not likely to change, the fixed-price contract offers a predictable cost. The responsibility for managing the work to meet the needs of the project is focused on the contractor. The project team tracks the quality and schedule progress to ensure the contractors will meet the project needs. The risks associated with fixed-price contracts are the costs associated with project change. If a change occurs on the project that requires a change order from the contractor, the price of the change is typically very high. Even when the price for changes is included in the original contract, changes on a fixed-price contract will create higher total project costs than other forms of contracts because the majority of the cost risk is transferred to the contractor, and most contractors will add a contingency to the contract to cover their additional risk.

Fixed-price contracts require the availability of at least two or more suppliers that have the qualifications and performance histories that ensure the needs of the project can be met. The other requirement is a scope of work that is most likely not going to change. Developing a clear scope of work based on good information, creating a list of highly qualified bidders, and developing a clear contract that reflects that scope of work are critical aspects of a good fixed-priced contract.

If the service provider is responsible for incorporating all costs, including profit, into the agreed-on price, it is a fixed-total-cost contract. The contractor assumes the risks for unexpected increases in labor and materials that are needed to provide the service or materials and in the materials and timeliness needed.

The fixed-price contract with price adjustment is used for unusually long projects that span years. The most common use of this type of contract is the inflation-adjusted price. In some countries, the value of its local currency can vary greatly in a few months, which affects the cost of local materials and labor. In periods of high inflation, the client assumes the risk of higher costs due to inflation, and the contract price is adjusted based on an inflation index. The volatility of certain commodities can also be accounted for in a price-adjustment contract. For example, if the price of oil significantly affects the costs of the project, the client can accept the oil price volatility risk and include a provision in the contract that would allow the contract price adjustment based on a change in the price of oil.

The fixed-price contract with incentive fee provides an incentive for performing on the project above the established baseline in the contract. The contract might include an incentive for completing the work on an important milestone for the project. Often contracts have a penalty clause if the work is not performed according to the contract. For example, if the new software is not completed in time to support the implementation of the training, the contract might penalize the software company a daily amount of money for every day the software is late. This type of penalty is often used when the software is critical to the project and the delay will cost the project significant money.

If the service or materials can be measured in standard units, but the amount needed is not known accurately, the price per unit can be fixed—a fixed-unit-price contract. The project team assumes the responsibility of estimating the number of units used. If the estimate is not accurate, the contract does not need to be changed, but the project will exceed the budgeted cost.

| Type | Known Scope | Share of Risk | Incentive for Meeting Milestones | Predictability of Cost |

|---|---|---|---|---|

| Fixed total cost | Very High | All contractor | Low | Very high |

| Fixed unit price | High | Mostly project | Low | High |

| Fixed price with incentive fee | High | Mostly project | High | Medium-high |

| Fixed fee with price adjustment | High | Mostly project | Low | Medium |

Cost-Reimbursable Contracts

In a cost-reimbursable contract, the organization agrees to pay the contractor for the cost of performing the service or providing the goods. Cost-reimbursable contracts are also known as cost-plus contracts. Cost-reimbursable contracts are most often used when the scope of work or the costs for performing the work are not well known. The project uses a cost-reimbursable contract to pay the contractor for allowable expenses related to performing the work. Since the cost of the project is reimbursable, the contractor has much less risk associated with cost increases. When the costs of the work are not well known, a cost-reimbursable contract reduces the amount of money the bidders place in the bid to account for the risk associated with potential increases in costs. The contractor is also less motivated to find ways to reduce the cost of the project unless there are incentives for supporting the accomplishment of project goals.

Cost-reimbursable contracts require good documentation of the costs that occurred on the project to ensure that the contractor gets paid for all the work performed and to ensure that the organization is not paying for something that was not completed. The contractor is also paid an additional amount above the costs. There are several ways to compensate the contractor.

- A cost-reimbursable contract with a fixed fee provides the contractor with a fee, or profit amount, that is determined at the beginning of the contract and does not change.

- A cost-reimbursable contract with a percentage fee pays the contractor for costs plus a percentage of the costs, such as 5% of total allowable costs. The contractor is reimbursed for allowable costs and is paid a fee.

- A cost-reimbursable contract with an incentive fee is used to encourage performance in areas critical to the project. Often the contract attempts to motivate contractors to save or reduce project costs. The use of the cost reimbursable contract with an incentive fee is one way to motivate cost-reduction behaviors.

- A cost-reimbursable contract with award fee reimburses the contractor for all allowable costs plus a fee that is based on performance criteria. The fee is typically based on goals or objectives that are more subjective. An amount of money is set aside for the contractor to earn through excellent performance, and the decision on how much to pay the contractor is left to the judgment of the project team. The amount is sufficient to motivate excellent performance.

On small activities that have a high uncertainty, the contractor might charge an hourly rate for labour, plus the cost of materials, plus a percentage of the total costs. This type of contract is called time and materials (T&M). Time is usually contracted on an hourly rate basis and the contractor usually submits time sheets and receipts for items purchased on the project. The project reimburses the contractor for the time spent based on the agreed-on rate and the actual cost of the materials. The fee is typically a percentage of the total cost.

T&M contracts are used on projects for work that is smaller in scope and has uncertainty or risk. The project, rather than the contractor, assumes the risk. Since the contractor will most likely include contingency in the price of other types of contracts to cover the high risk, T&M contracts provide lower total cost to the project.

| Cost Reimbursable (CR) | Known Scope | Share of Risk | Incentive for Meeting Milestones | Predictability of Cost |

|---|---|---|---|---|

| CR with fixed fee | Medium | Mostly project | Low | Medium-high |

| CR with percentage fee | Medium | Mostly project | Low | Medium-high |

| CR with incentive fee | Medium | Mostly project | High | Medium |

| CR with award fee | Medium | Mostly project | High | Medium |

| Time and Materials | Low | All project | Low | Low |

To minimize the risk to the project, the contractor typically includes a not-to-exceed amount, which means the contract can only charge up to the agreed amount. The T&M contract allows the project to make adjustments as more information is available. The final cost of the work is not known until sufficient information is available to complete a more accurate estimate.

Progress Payments and Change Management

Vendors and suppliers usually require payments during the life of the contract. On contracts that last several months, the contractor will incur significant cost and will want the project to pay for these costs as early as possible. Rather than wait until the end of the contract, a schedule of payments is typically developed as part of the contract and is connected to the completion of a defined amount of work or project milestones. These payments made before the end of the project and based on the progress of the work are called progress payments. For example, the contract might develop a payment schedule that pays for the design of the curriculum, then the development of the curriculum, and then a final payment is made when the curriculum is completed and accepted. In this case there would be three payments made. There is a defined amount of work to be accomplished, a time frame for accomplishing that work, and a quality standard the work must achieve before the contractor is paid for the work.

Just as the project has a scope of work that defines what is included in the project and what work is outside the project, vendors and suppliers have a scope of work that defines what they will produce or supply to the company. (Partners typically share the project scope of work and may not have a separate scope of work.) Often changes occur on the project that require changes in the contractor’s scope of work. How these changes will be managed during the life of the project is typically documented in the contract. Capturing these changes early, documenting what changed and how the change impacted the contract, and developing a change order (a change to the contract) are important to maintaining the progress of the project. Conflict among team members may arise when changes are not documented or when the team cannot agree on the change. Developing and implementing an effective change management process for contractors and key suppliers will minimize this conflict and the potential negative effect on the project.

Procurement Process

The project procurement cycle reflects the procurement activities from the decision to purchase the material or service through to the payment of bills and closing of procurement contracts.

The process is summarised in the video below.

(Click the image to access the video)

Procurement Plan

After the decision has been made to purchase goods or outsource services, the procurement team develops a plan that includes the following:

- Selecting the appropriate relationships and contract approaches for each type of purchased goods or outsourced service

- Preparing requests for quotes (RFQs) and requests for proposals (RFPs) and evaluating partnership opportunities

- Evaluating RFQs, RFPs, and partnerships

- Awarding and signing contracts

- Managing quality and timely performance

- Managing contract changes

- Closing contracts

Depending on the complexity level of the project, each of these steps can take either hours or sometimes weeks of work to complete. Each of these steps is also included in the project master schedule. The time involved in the procurement cycle can influence the scheduling of critical activities, including the decision to self-perform the work or contract the work to others. The delivery dates for equipment and materials and the work completion dates for contracted works are placed on the project schedule. Any procurement activities that create a project delay or fall on the project critical path may require special attention.

Selecting the Contract Approach

The technical teams typically develop a description of the work that will be outsourced. From this information, the project management team answers the following questions:

- Is the required work or materials a commodity, customized product or service, or unique skill or relationship?

- What type of relationship is needed: supplier, vendor, or partnership?

- How should the supplier, vendor, or potential partner be approached: RFQ, RFP, or personal contact?

- How well known is the scope of work?

- What are the risks and which party should assume which types of risk?

- Does the procurement of the service or goods affect activities on the project schedule’s critical path and how much float is there on those activities?

- How important is it to be sure of the cost in advance?

The procurement team uses the answers to the first three questions listed above to determine the approach to obtaining the goods or services and the remaining questions to determine what type of contract is most appropriate.

A key factor in selecting the contract approach is determining which party will take the most risk. The team determines the level of risk that will be managed by the project and what risks will be transferred to the contractor. Typically, the project management team wants to manage the project risk, but in some cases, contractors have more expertise or control that enable them to better manage the risk associated with the contracted work.

Let’s review the contract types in this video as per guided in the PMBOK guide chapter 12.

(Click the image below to access the video)

Soliciting Bids

A solicitation is the process of requesting a price and supporting information from bidders. The solicitation usually takes the form of either an RFQ or an RFP. Partnerships are pursued and established differently on a case-by-case basis by senior management.

Qualifying Bidders

Potential bidders are people or organizations capable of providing the materials or performing the work required for the project. On smaller, less complex projects, the parent company typically has a list of suppliers and vendors that have successfully provided goods and services in the past, and the project has access to the performance record of companies on that list. On unique projects, where no supplier lists exist, the project team develops a list of potential suppliers and then qualifies them to become eligible to bid on project work. Eligible bidders are placed on the bidders list and provided with a schedule of when work on the project will be put out for bid.

The eligibility of a supplier is determined by the ability to perform the work in a way that meets project requirements and demonstrates financial stability. Ability to perform the work includes the ability to meet quality specifications and the project schedule. During times when economic activity is high in a region, many suppliers become busy and stretch their resources. The project team investigates the potential suppliers, before they are included on the bidder’s list, to ensure that they have the capacity and track record to meet deadlines.

The potential supplier must also be financially stable to be included on the bidders list. A credit check or a financial report from Dun and Bradstreet (D&B)—a well-known provider of financial information about individual companies—will provide the project with information about the potential bidder’s financial status. D&B services include the following:

- D&B proprietary rankings and predictive creditworthiness scores

- Public filings, including suits, liens, judgments, and UCC (uniform commercial code) filings—standardized financial disclosure documents that conform to the uniform commercial code

- Company financial statements and history

Request for Quote

An RFQ focuses on price. The type of materials or service is well defined and can be obtained from several sources. The bidder that can meet the project quality and schedule requirements usually wins the contract by quoting the lowest price.

Request for Proposal

An RFP accounts for price but focuses on meeting the project quality or schedule requirements. The process of developing a proposal in response to an RFP can be very expensive for the bidder, and the project team should not issue an RFP to a company that is not eligible to win the bid.

Evaluating Bids

Evaluation of bids in response to RFQs for commodity items and services is heavily graded for price. In most cases, the lowest total price will win the contract. The total price will include the costs of the goods or services, any shipping or delivery costs, the value of any warranties, and any additional service that adds value to the project.

The evaluation of bids based on RFPs is more complex. The evaluation of proposals includes the price and also an evaluation of the technical approach chosen by the bidder. The project team evaluating the proposal must include people with the expertise to understand the technical aspects of the various proposal options and the value of each proposal to the project. On more complex projects, the administrative part of the proposal is evaluated and scored by one team, and the technical aspect of the proposal is evaluated by another team. The project team combines the two scores to determine the best proposal for the project.

Awarding the Contract

After the project team has selected the bidder that provides the best value for the project, a project representative validates all conditions of the bid and the contract with the potential contractor. Less complex awards, like contracts for printed materials, require a reading and signing of the contract to ensure that the supplier understands the contract terms and requirements of the project schedule. More complex projects require a detailed discussion of the goals, the potential barriers to accomplishing those goals, the project schedule and critical dates, and the processes for resolving conflicts and improving work processes.

Managing the Contracts

The contract type determines the level of effort and the skills needed to manage the contract. The manager of supplier contracts develops detailed specifications and ensures compliance with these specifications. The manager of vendor contracts ensures that the contractors bidding on the work have the skills and capacity to accomplish the work according to the project schedule and tracks the vendor’s performance against the project needs, supplying support and direction when needed. The manager of partnering arrangements develops alignment around common goals and work processes. Each of these approaches requires different skills and various degrees of effort.

Items that take a long time to acquire—long-lead items—receive early attention by the project leadership. Examples of long-lead items are equipment that is designed and built specifically for the project, curriculum that is created for training a new workforce, and a customized bioreactor for a biotech project. These items might require weeks, months, or years to develop and complete. The project team identifies long-lead items early to begin the procurement activities as soon as possible because those procured through the normal procurement cycle may cause delays in the project.

After the contract is awarded, the project team tracks the performance of the contractor against performance criteria in the contract and his or her contribution to the performance of the project. Usually, contractors deliver the product or service that meets the quality expectations and supports the project schedule. Typically, there are also one or two contractors that do not perform to project expectations. Some project managers will refer to the contract and use it to attempt to persuade the contractor to improve performance or be penalized. Other project managers will explore with the contractor creative ways to improve performance and meet project requirements. The contract management allows for both approaches to deal with non`-performing contractors, and the project team must assess what method is most likely to work in each situation.

Managing contractor performance on a project is as important to the overall project outcomes as the work performed by the project team.

Logistics and Expediting

Equipment and materials that are purchased for use on the project must be transported, inventoried, warehoused, and often secured. This area of expertise is called logistics. The logistics for the project can be managed by the project team or can be included in the RFP or RFQ. On international projects, materials may be imported, and the procurement team manages the customs process. On smaller projects, the logistical function is often provided by the parent company. On larger projects, these activities are typically contracted to companies that specialize in logistical services. On larger, more complex projects, the procurement team will include logistical expertise.

The project work often depends on materials procured for the project. The delivery of these materials influences the scheduling of the project, and often some materials are needed earlier than normal procurement practices would deliver. On long-lead items, the project schedule is included in the contracting plans and contractors must explain how they will support the project schedule.

On large, complex projects, critical items might be scheduled for delivery after they are needed on the project. The procurement team then explores ideas with the contractor to expedite the manufacturing or transportation of the equipment or materials. The contract can often place a priority on the fabrication of the equipment and delivery of the equipment to meet the project schedule. The project logistics team can also explore ways of shortening the transportation time. For example, a project in Argentina flew some critical equipment from Sweden rather than transport the equipment by ship to save several weeks in transit. The logistics costs were higher, but the overall value to the project was greater.

Text Attributions

This section contains material derived and remixed from the following sources:

- Project Management – 2nd Edition by Adrienne Watt is licensed under CC BY (Attribution) 4.0 International License

- Project Management for Instructional Designers by Wiley et. al. is licensed under CC BY NC SA (Attribution-NonCommercial-ShareAlike) 4.0